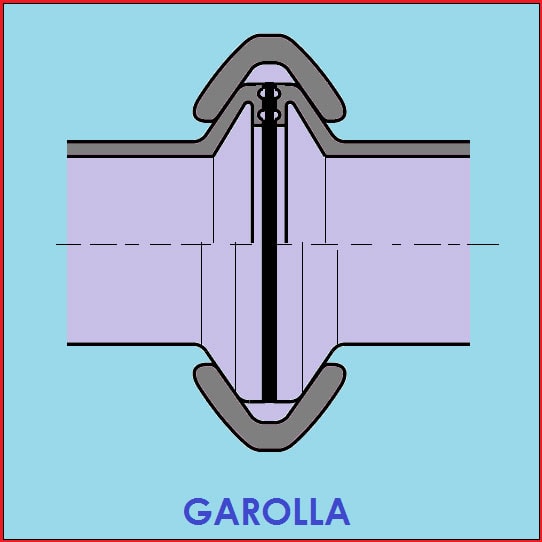

The connection more widespread in the wine producing sector is the one obtained through stainless steel fittings and clamps called Garolla. Very similar in concept to other types of clamp fittings, it is composed of two identical unions, each of which may have a corrugated end (to be inserted in the terminal part of the pipe and tightened by a clamp through this metal) and the opposite end flared and curved edges.

The two pieces of the fitting, juxtaposed to one another, are joined permanently together by a metal clamp, after insertion of appropriate rubber seal for food use between the two ends to be connected. The clamp that provides this join is composed of two semicircles joined by a ring, and closed by a threaded shank and wing nut for manual screwing.

The advantages of these fittings are the durability and ease of assembly and disassembly operations that can be done by one person without the use of aids or tools of any kind. In contrast, they present difficulties for sanitization, which excludes their use in the bottling process, while they are widely used in all the other stages of the winemaking process. Enable the connection of the pipes between them and with the wine tanks, pumps, wine-making machines, etc…

Usually the connection is obtained with fittings having the same section as the hoses, but, if necessary, it is possible to connect pipes of different diameter through adapters or reduction gear, which, however, creates obvious bottlenecks with consequent flow turbulence and pressure losses.

To meet the different needs related to different processes of wineries, this family of connectors also includes a number of accessories such as bends, elbows, tees, Y unions, reducers and couplings between converters of various types.